Blue Corridor as Industrial Community Armature: A Resilient Transformation of Water and Social Network

Honor Award

General Design

Gegu, Tianjin, China

Youzi Xu, Student ASLA; Ziying Huang, Student ASLA

Faculty Advisors: Muhan Cui, ASLA; Nicola Saladino; Chen Chen; Ellen Neises

University of Pennsylvania

This proposal to transform a city’s struggling water systems addresses the social and cultural importance of water and industry in Tianjin, China. It is an interesting take; a lot of times we look at what is left over from industry, but we look less often at the ways those leftovers can be integrated into a public asset. These students instead impressively propose an active factory that improves water access and quality while also educating the public about where their water comes from and how it is processed.

- 2021 Awards Jury

Project Statement

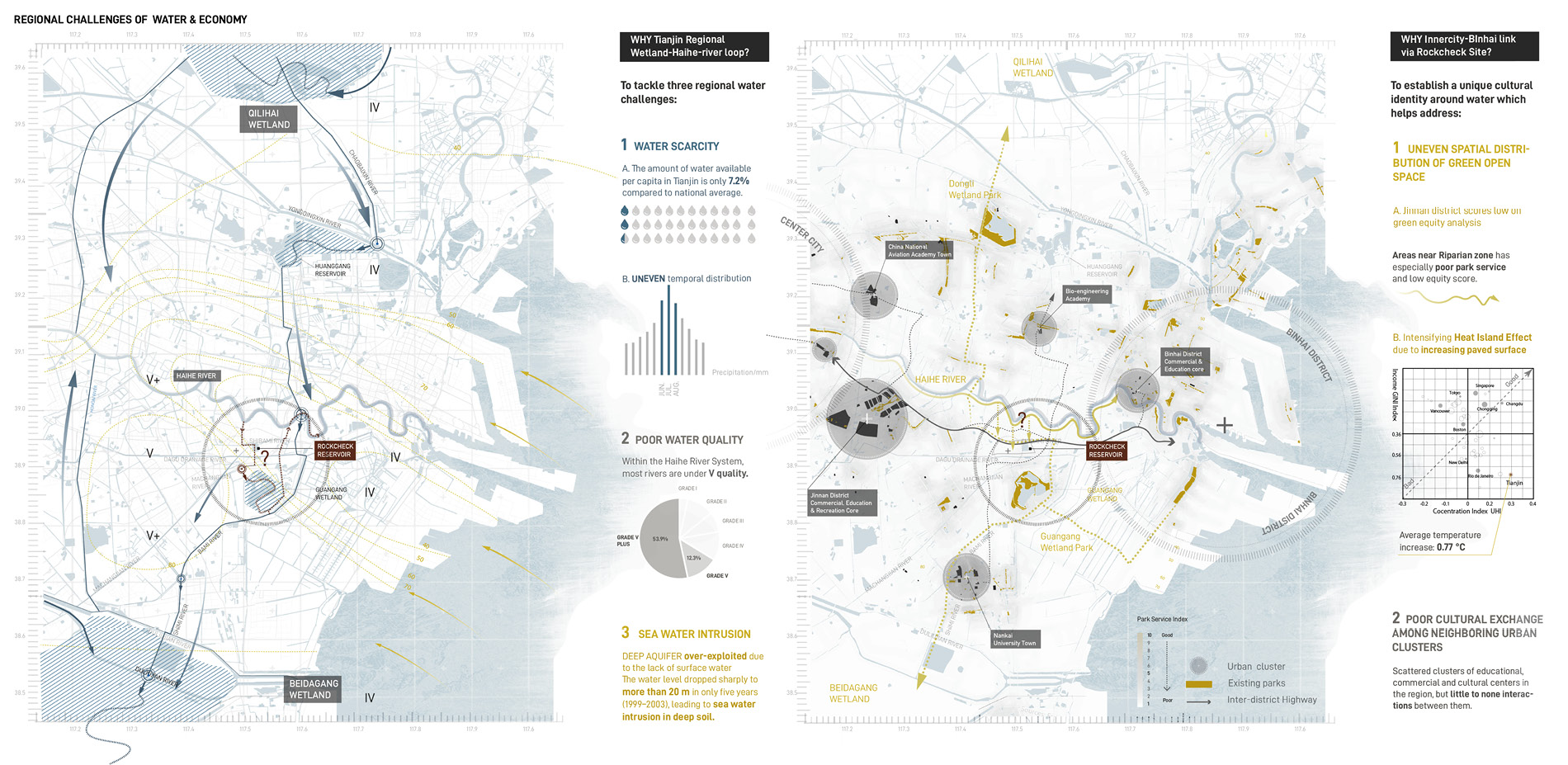

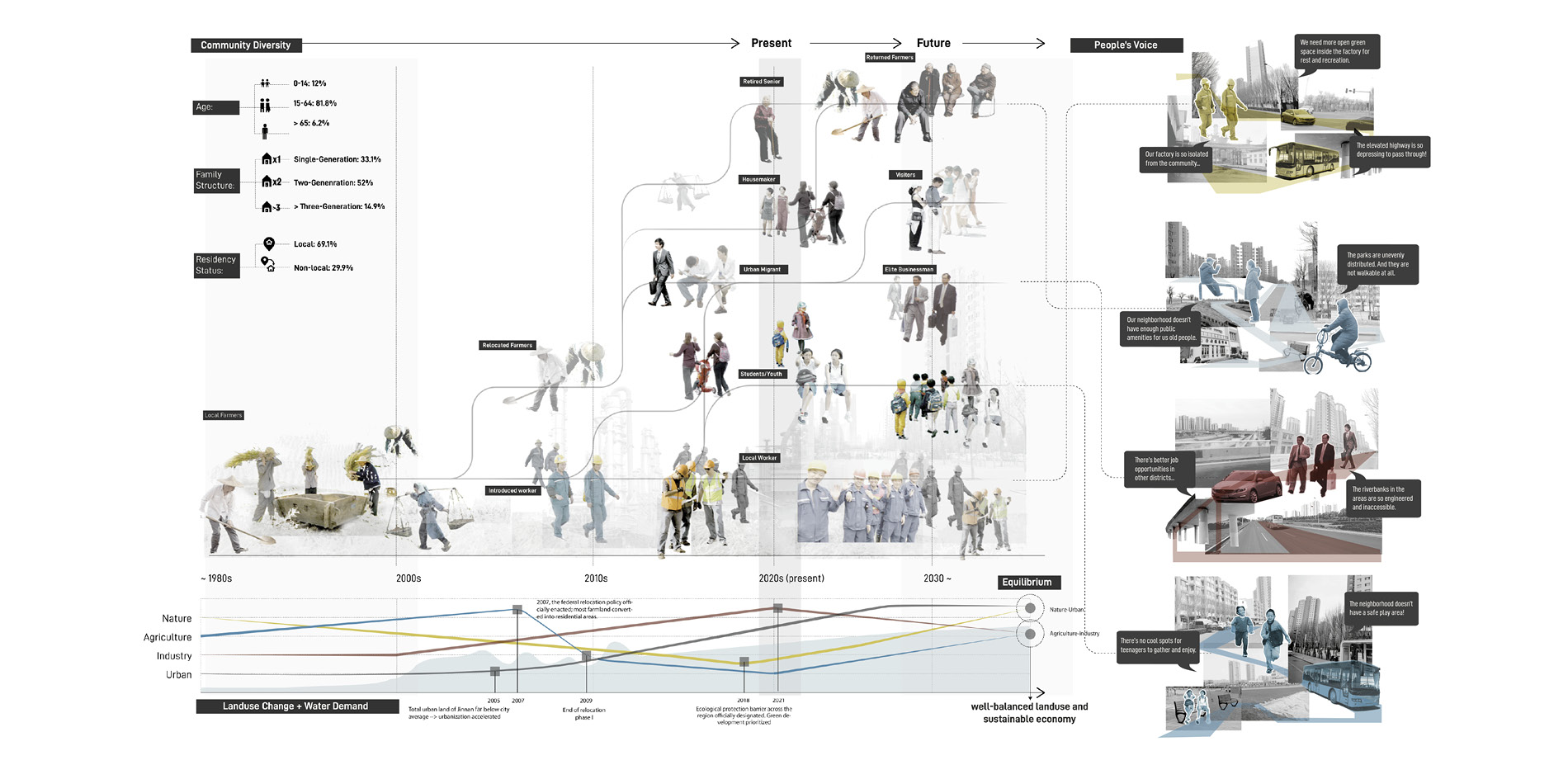

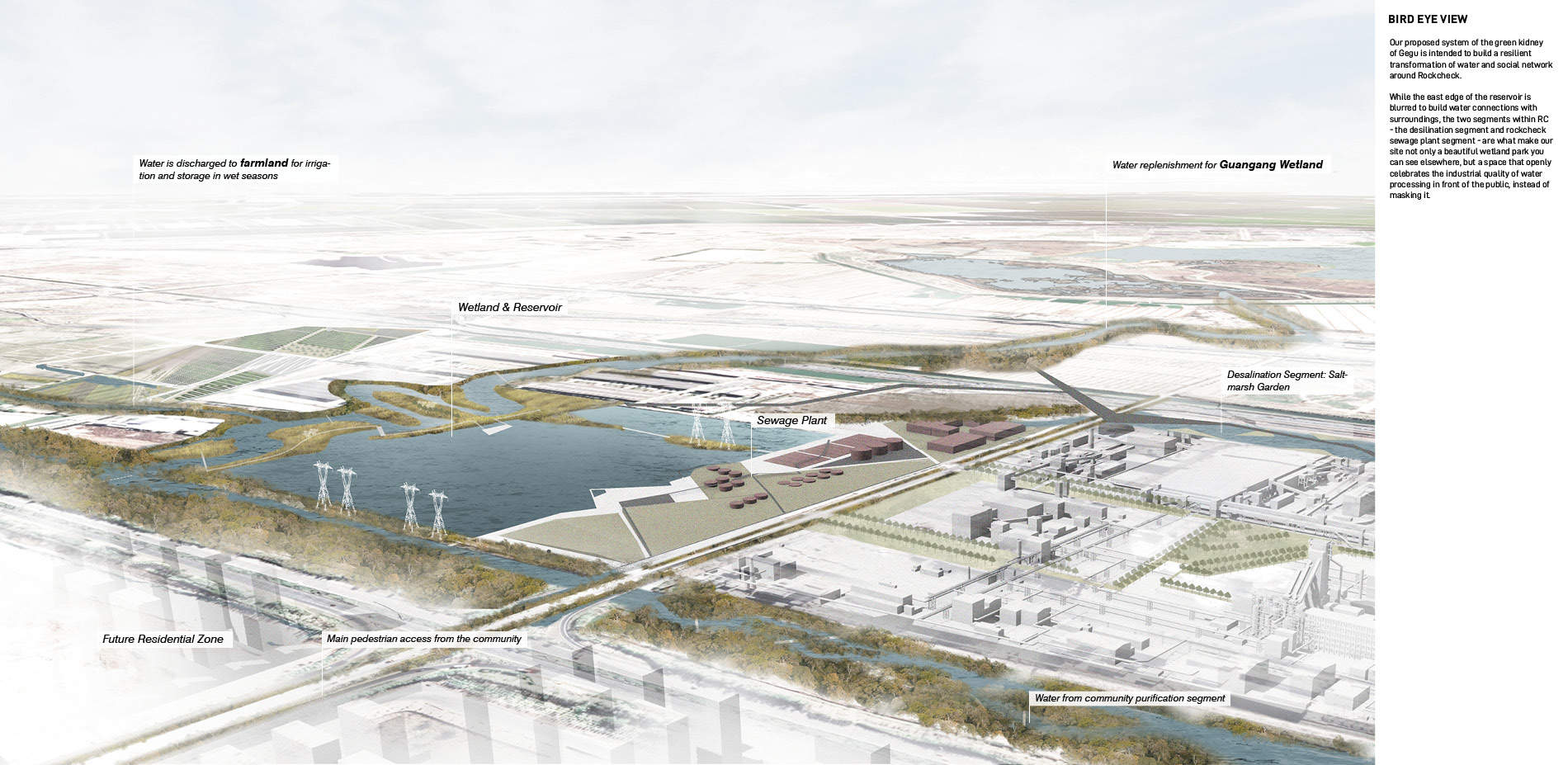

Tianjin, as the port city with an ongoing legacy of coastal trades and industries, is now facing severe hydrological problems: the scarcity, accelerating upstream pollution, and high groundwater salinity. Situated in such context, compounded by its unique industrial heritage now threatened by the top-down land-use&relocation policy, the town of Gegu with Rockcheck Steel Plant as its biggest manufacturer urges a resilient framework to both honor its cultural identity as an industrial powerhouse and restore a healthy link between the people and water.

By transforming the invisible to visible, imperceptible to sensible within proposed blue corridor, a new cultural nexus is formed for people to innovatively participate in various treatment processes which address local and regional water crisis, while also attracting external flows of users and investments to the region. The steel-making industry acts both as a strong collaborator and a co-beneficiary during such process, performing a sustainable counter-act against its own outdating production modes. This project thus takes a stand as a prototype for industry and people co-evolving in lieu of changing environment.

Project Narrative

Colloquially known as JingJinJi, the Beijing-Tianjin-Hebei region has long been the economic capital of China. Beginning 2020, the Chinese government has been pressuring the high-energy, high-pollution industries within the JingJinJi region to shift towards a more sustainable business model. As part of this initiative, the Rockcheck steel plant located between Tianjin City Center and Binhai CBD has been the main target of the top-down reformation, facing challenges of outdated production mode and declining social reputation among the local community.

Moreover, Tianjin, as the port city with an ongoing legacy of coastal trades and industries facilitated by the Haihe River and the two major wetlands surrounding it, is now facing severe hydrological problems. These issues include water scarcity, accelerating upstream pollution, and high groundwater salinity caused by seawater intrusion. In order to rebuild the water network, the city has implemented a regional project designed to strengthen the feedback-loop between the Haihe River and the two wetlands. Our proposal seeks to build upon this project and reimagine a blue corridor for the Rockcheck steel plant and into the surrounding waterways utilized by the community, to both honor its unique cultural identity as an industrial powerhouse and restore a healthy link between the people and water.

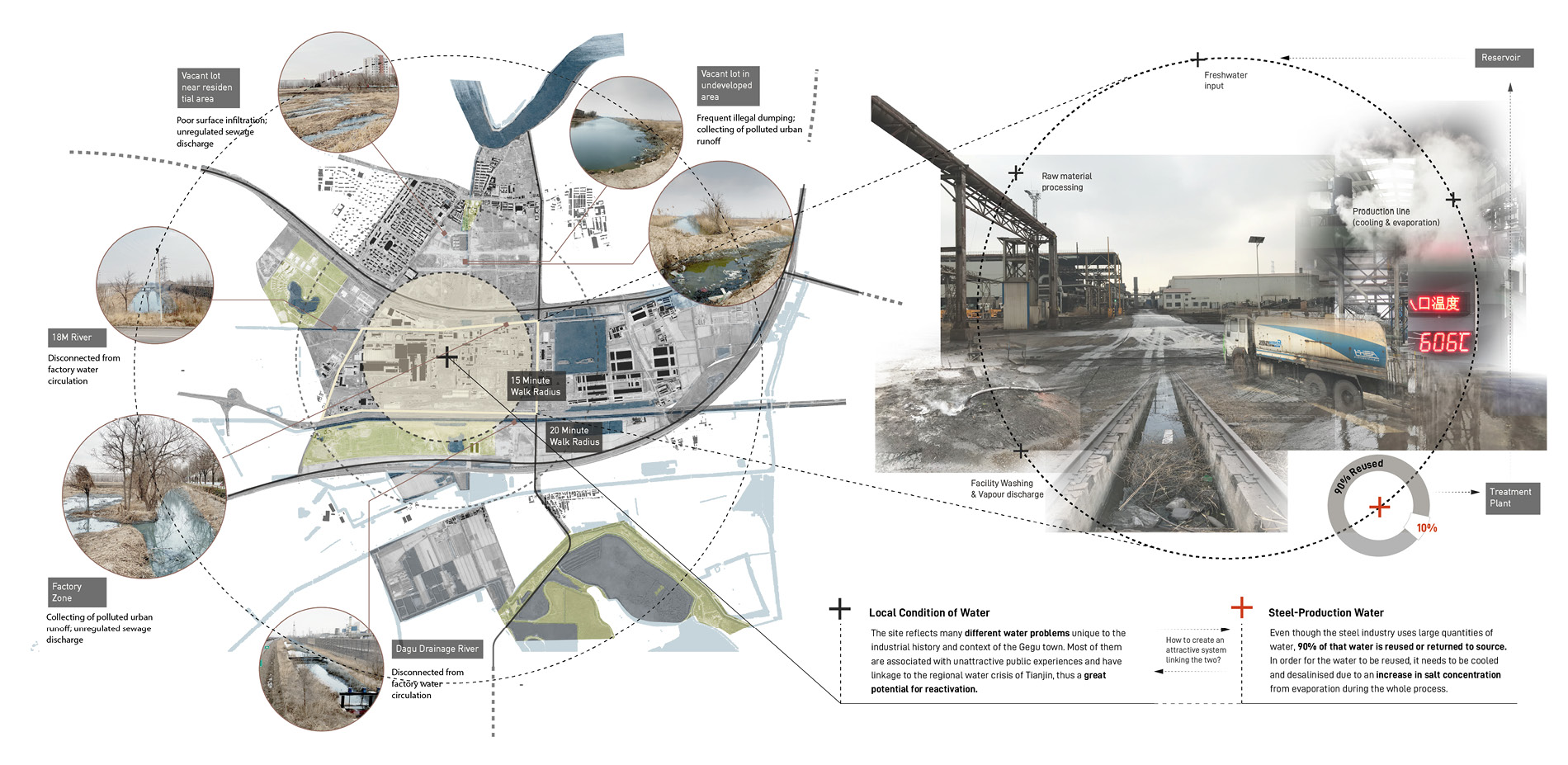

Site With a long history of industrial land use, the site around Rockcheck Steel Plant (RC) exemplify a heavily human-impacted hydrological system. In 2001, RC purchased large acreages of agricultural land for factory construction, converting the pastoral view of open wet-fields into a closed reservoir exclusive to steel production. This completely disconnects the water circulation from the rest of the network. The plant further expanded its property on the west-reservoir-periphery in 2008 with the addition of a sewage plant, used to process domestic sewage for steel-making water to meet the increasing demand. Although the water treatment facility and heat supply has benefited the local community, these efforts remain unseen largely due to physical barriers such as highways, fences, and inaccessible water channels segregating the factory from the peoples it serves.

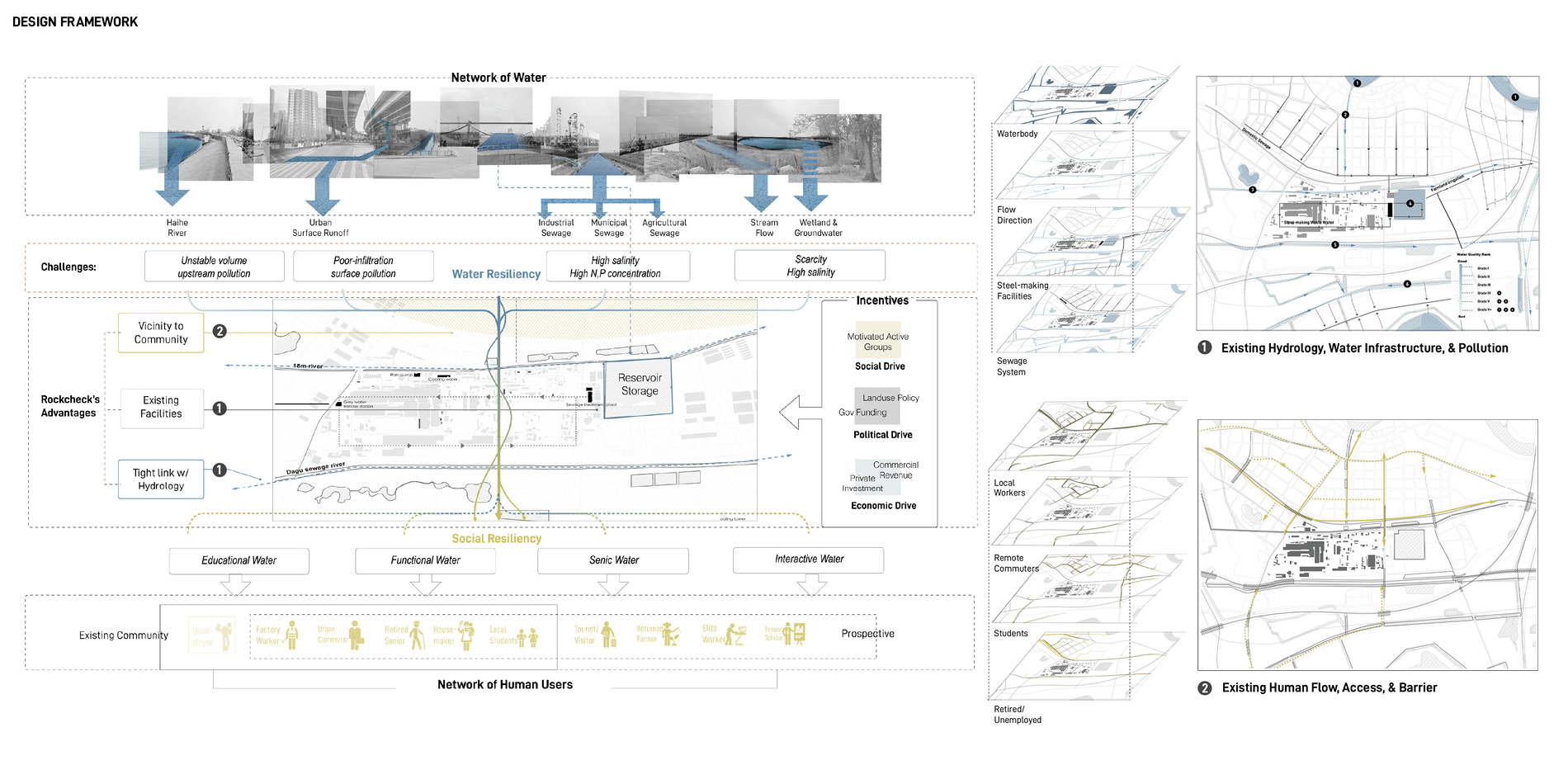

When juxtaposing the dynamic water processing loop inside of the factory and the broken water system outside of it, we begin to see great potential in linking the two to form a local blue corridor. The blue corridor will have a high eco-service value with stormwater management, sewage treatment, and clean water storage as well as high social value through tourism, education, and recreation.

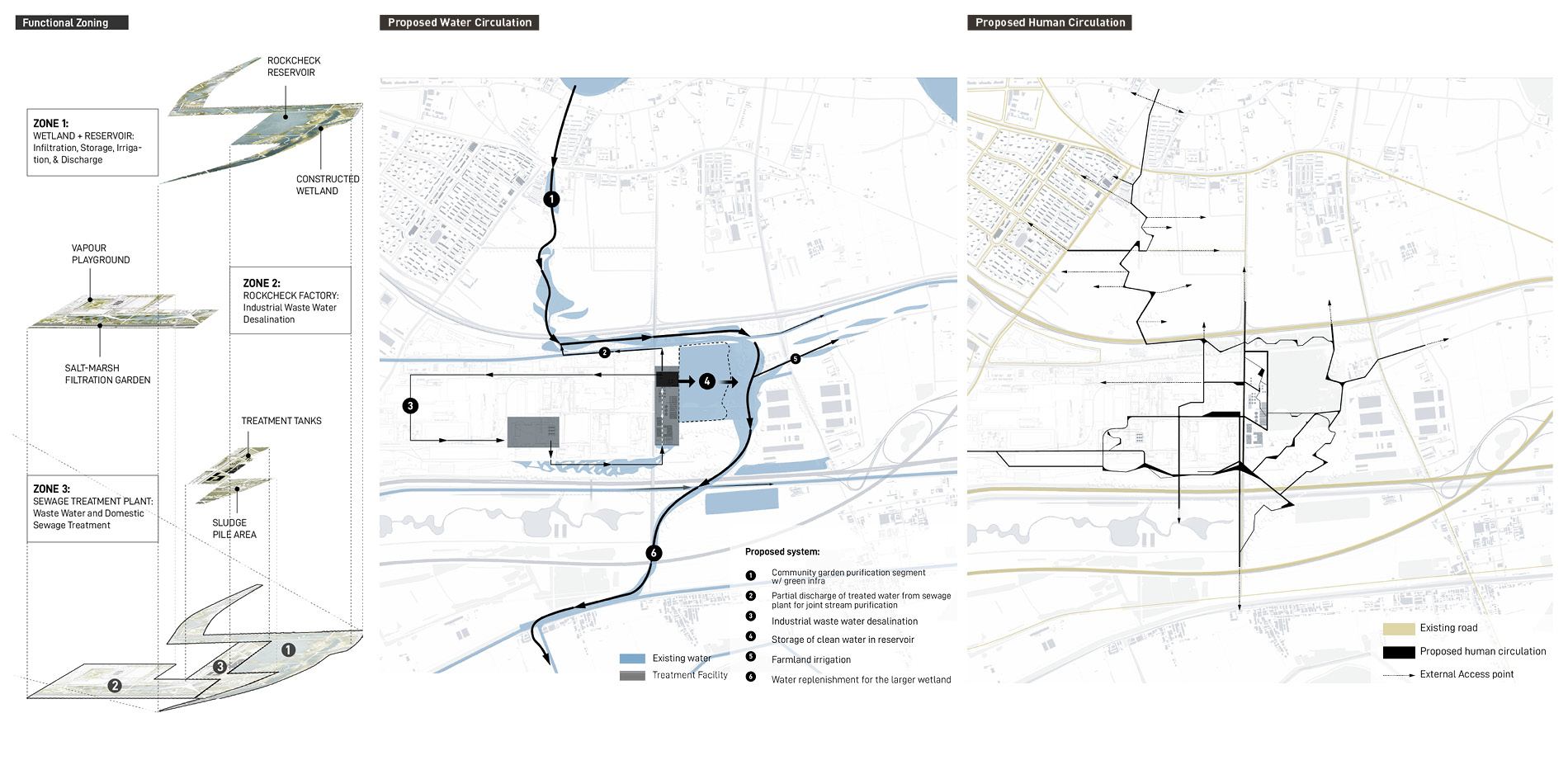

The proposed corridor system is broken down into three zones: constructed wetland and open reservoir, desalination garden, and sewage treatment plant. Pieced together, it not only showcases Gegu’s cultural identity, but also distinguishes the site from conventional wetlands parks with its high functionality.

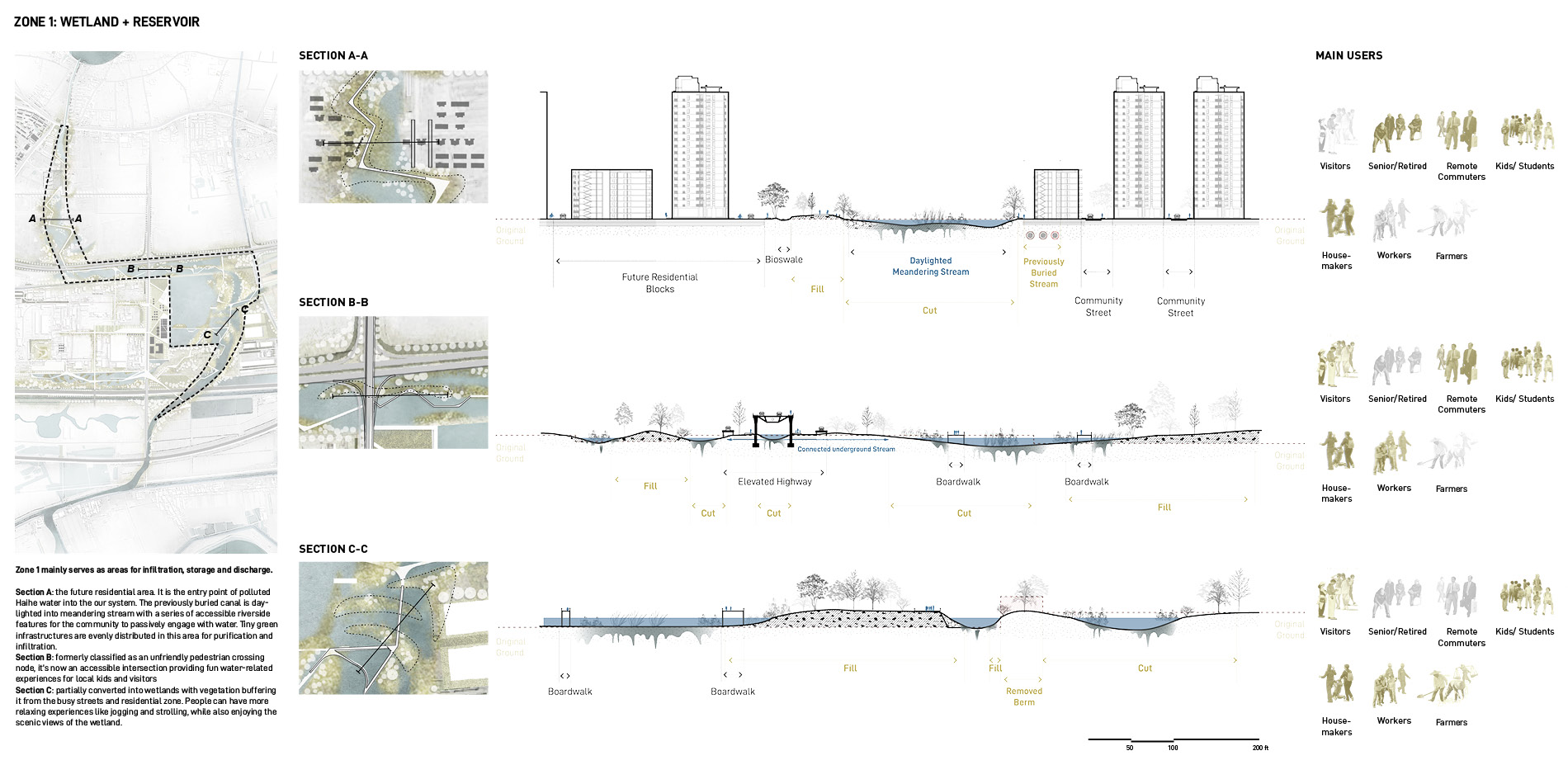

Zone 1 Zone 1 mainly serves as an area for infiltration, storage, and discharge. The existing hard edges are demolished to reconnect water to the larger circulation – the Haihe River, farmland, and Guangang wetland.

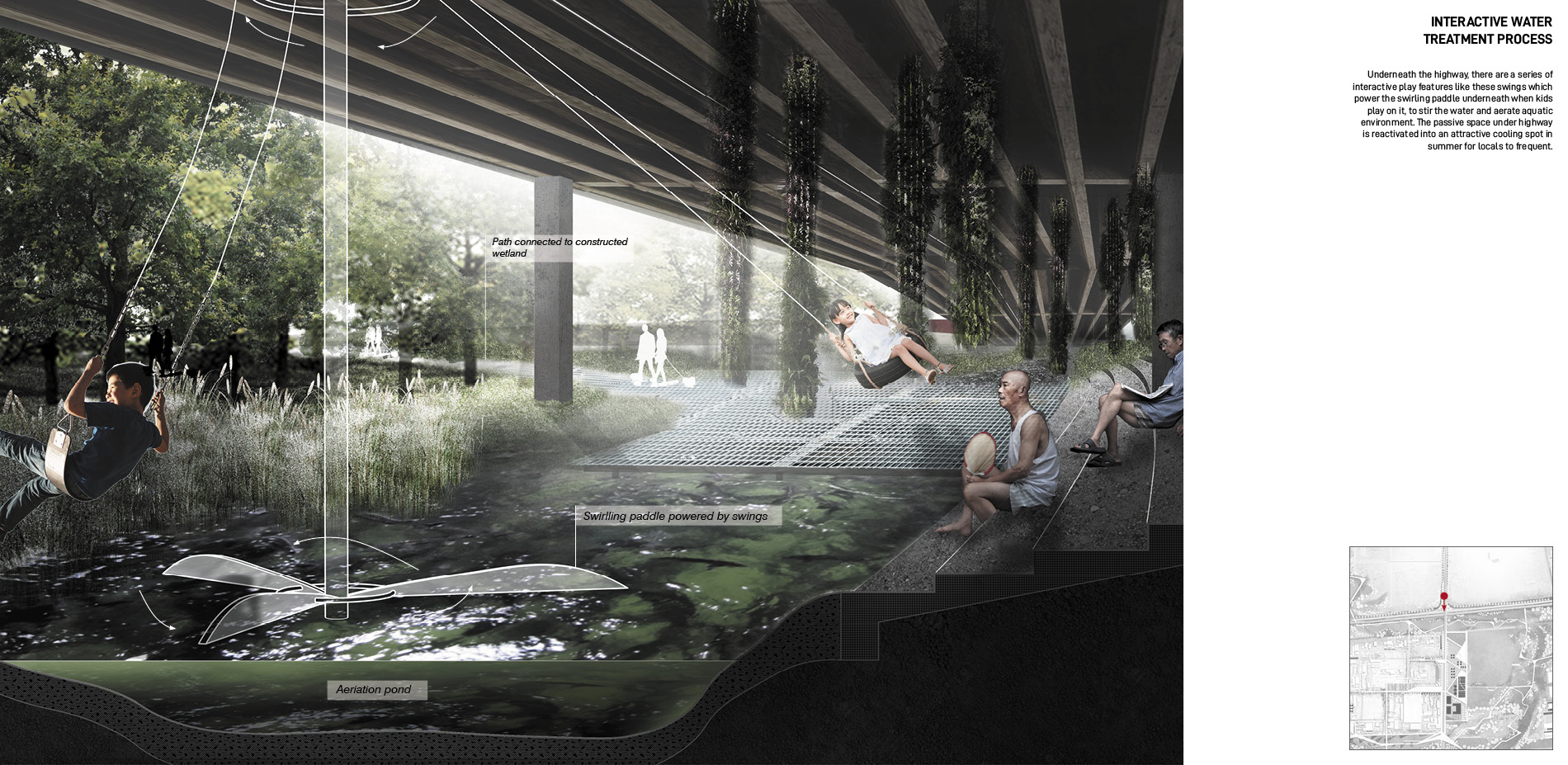

A newly dredged channel at the north confluence point with the Haihe River creates an entry point to pump in polluted upstream water into our proposed system. The previously buried canal across the developing residential area are daylighted into meandering streams with a series of accessible riverside features for the community to passively engage with the water. Additionally, tiny green infrastructures are evenly distributed in this area for urban runoff retention and infiltration. Areas under the existing Yingfang Highway, formerly classified as an unfriendly pedestrian crossing node, is now an accessible intersection providing fun water-related experiences for local kids and visitors. The Rockcheck reservoir concedes land that holds water in excess for new wetland development, with vegetation buffering it from the busy streets and residential zone for peaceful moments of recreation, such as jogging and strolling alongside the scenic views. Native species like Typha orientalis, Iris pseudacorus L., and Lythrun salicaria L. are planted with their scientifically-proven purification ability to accelerate the process of pollution removal, ensuring safe water quality for a certain degree of public interaction.

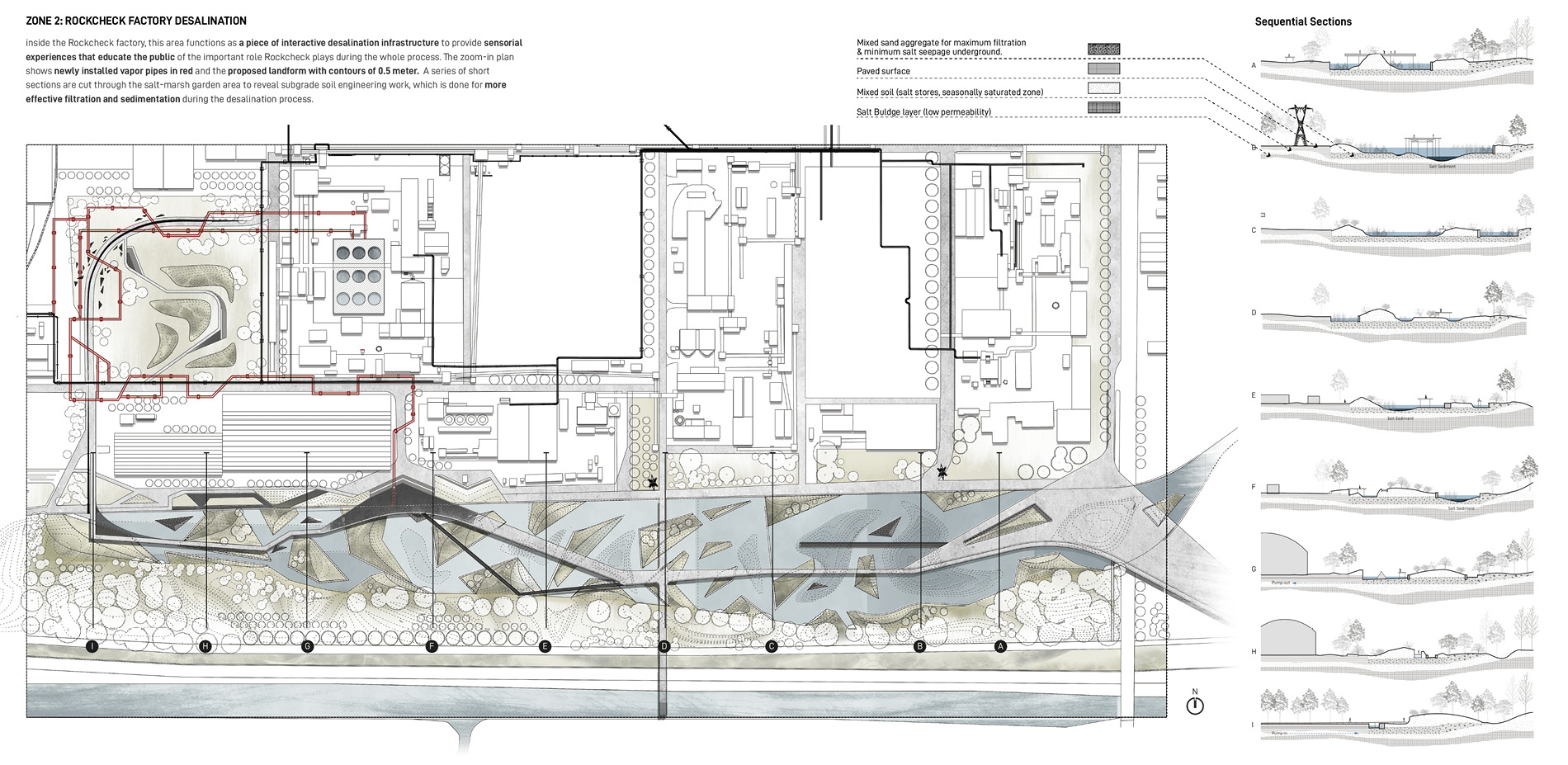

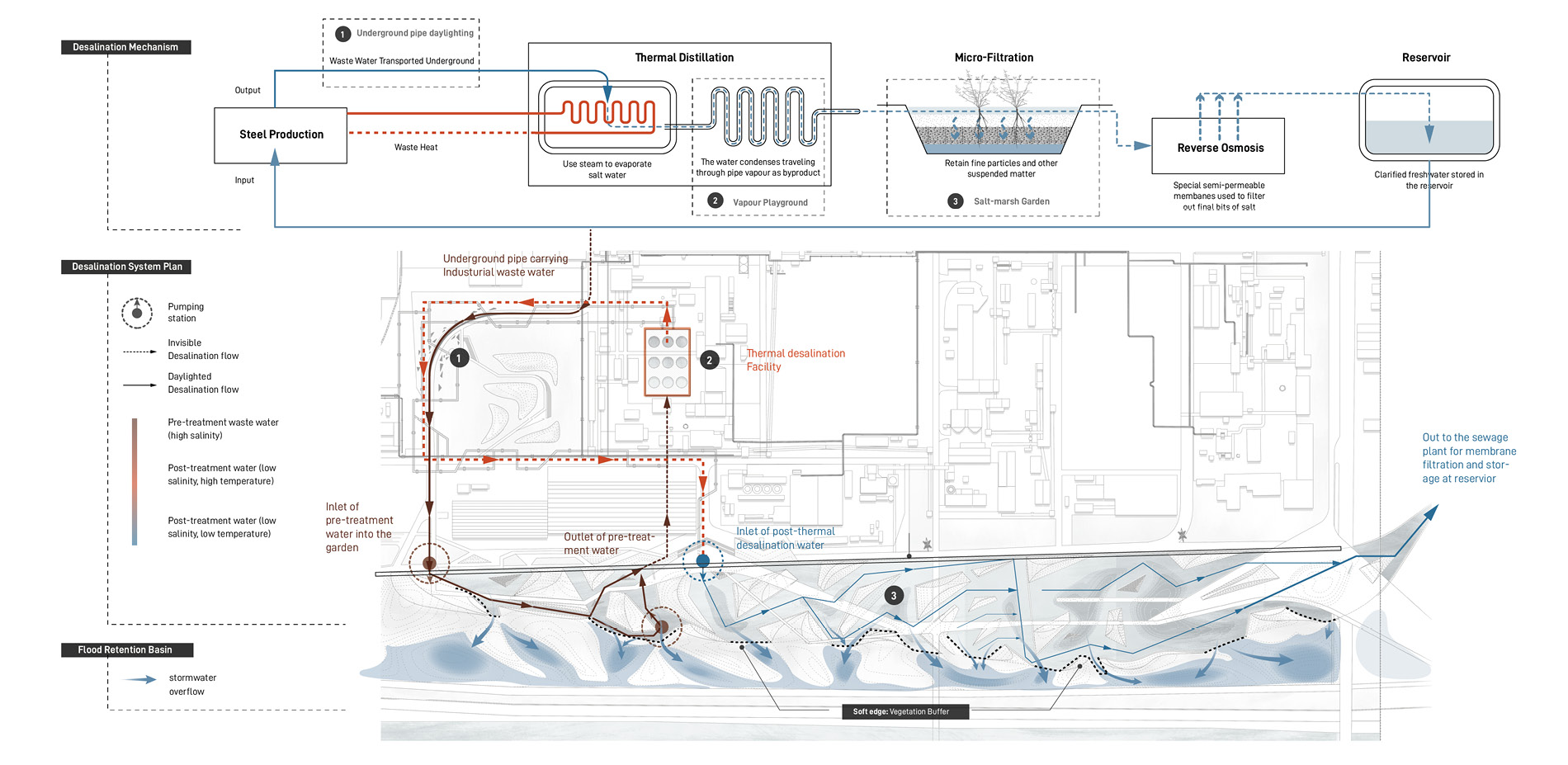

Zone 2 Utilizing waste heat from steel-making, Zone 2 functions as an interactive thermal desalination infrastructure to tackle high water salinity from industrial production. With the factory partially opened to the public as part of a water treatment education tour, it breaks the boundary between isolated workers and other user types for better social exchange.

The whole desalination process involves three main procedures: thermal distillation, micro-filtration, and reverse osmosis before its ultimate storage in the reservoir. Conventionally performed in either underground pipes or fenced facilities, those low hazard processes are now embodied in a series of daylighted educational and recreational landscape features.

The pre-treatment water would first enter into a small portion of the salt marsh garden to simulate a highly saline environment where only certain halophyte species can thrive, constructing unique horticultural characteristics of color and form. Then, this water is pumped back into the thermal distillation facility, using waste heat from the factory to be distilled and cooled down in pipes. The vapor produced in this step is efficiently used as another playful feature within the plaza for people to engage with. Varying forms of saline water before and after the treatment is made visible, educating people of the fast-paced nature of industrial material processing.

As the treated water is pumped to the second half of the garden, plants will facilitate micro-filtration while engineered soil will retain finer particles. The saline environment induces transformation of both the organic and inorganic matters within the garden. The salt-tolerant plants, saline-alkaline soil, and salt-corroded recycled steel art installations give visitors visual cues of the temporal quality of salinity.

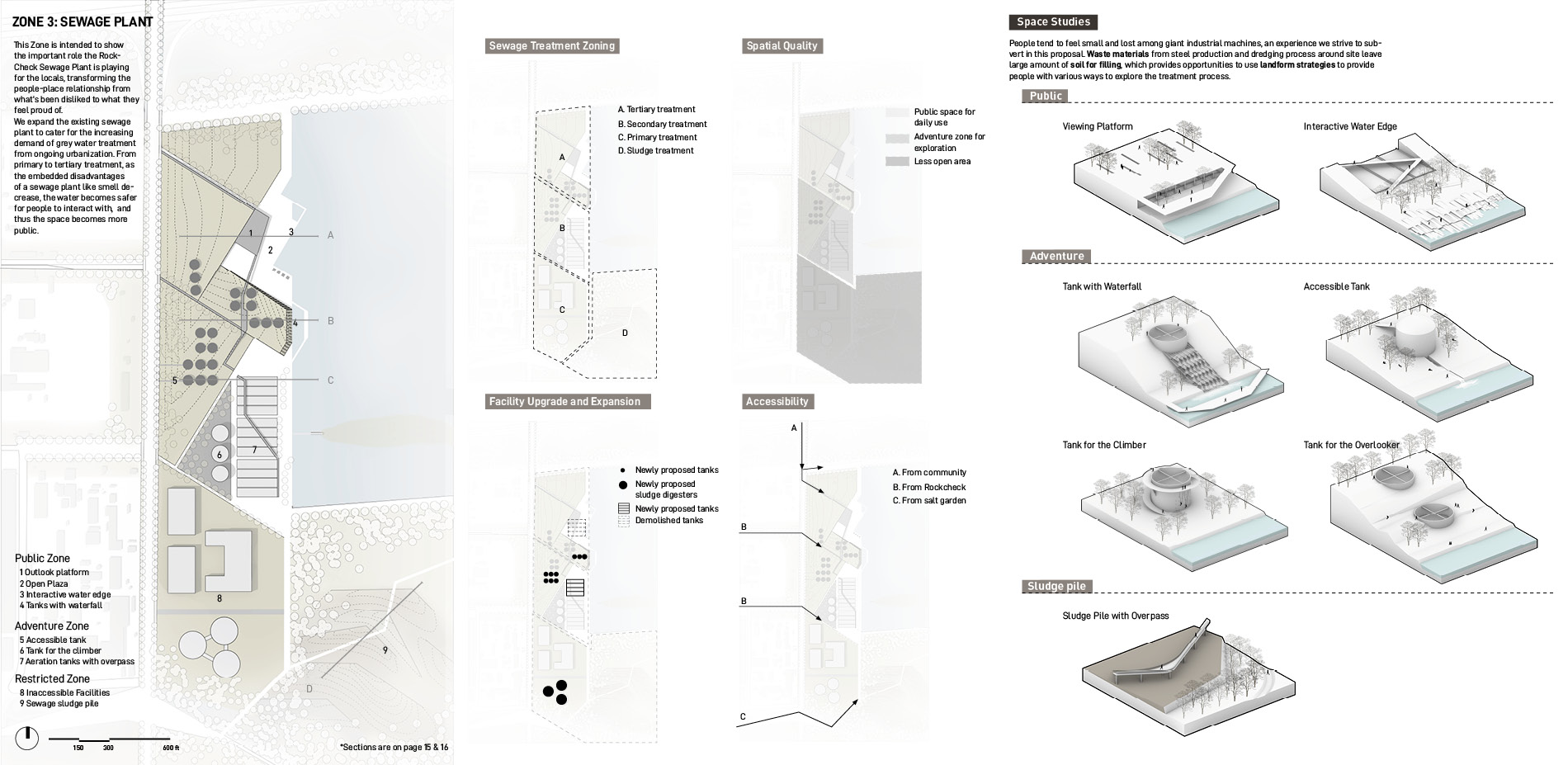

Zone 3 This zone illustrates the indispensable role Rockcheck Sewage Plant is playing for the community through active sensorial engagement such as touch, smell, and sound and transforming the people-place relationship from a negative association to acknowledgement with pride.

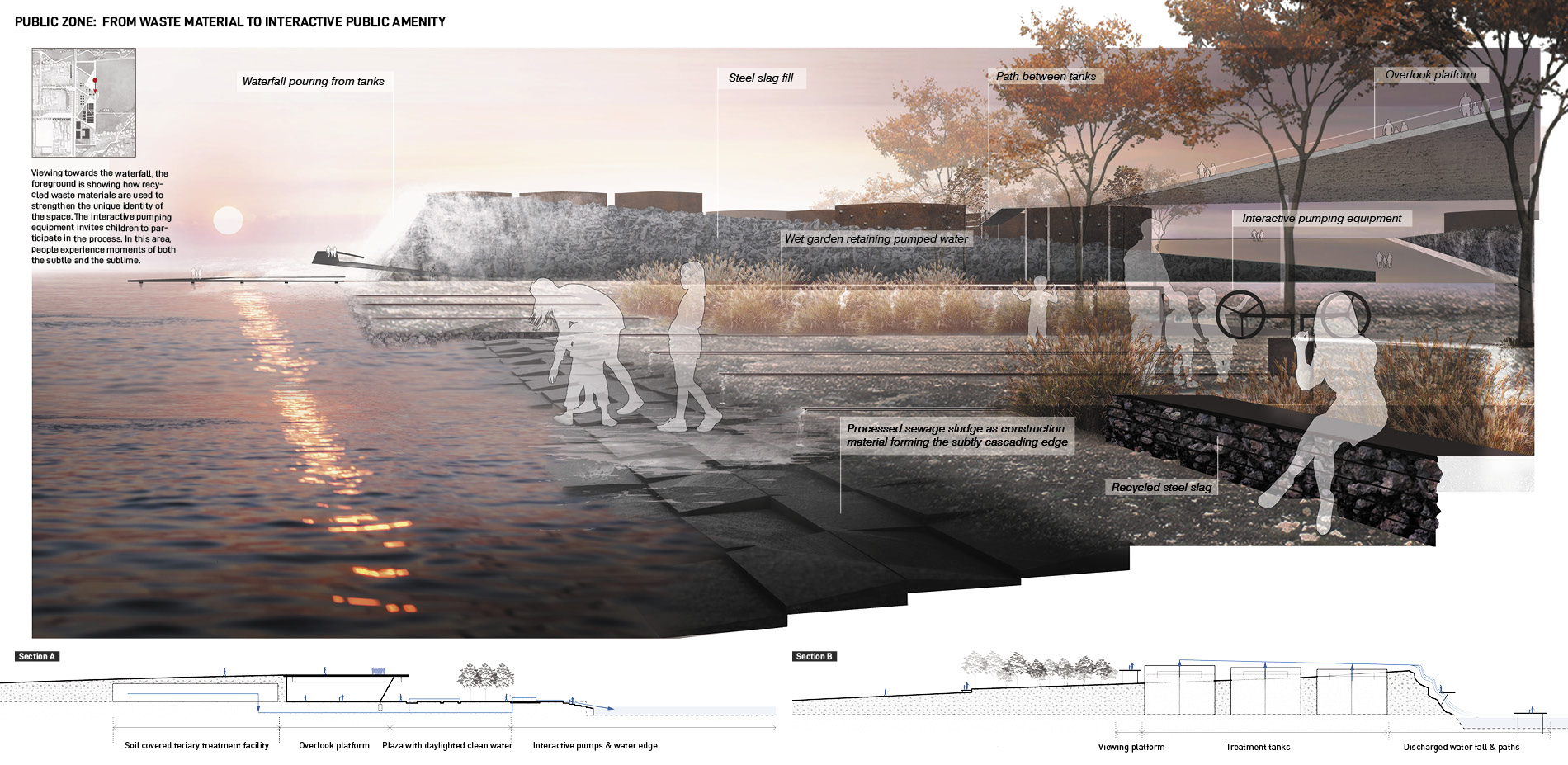

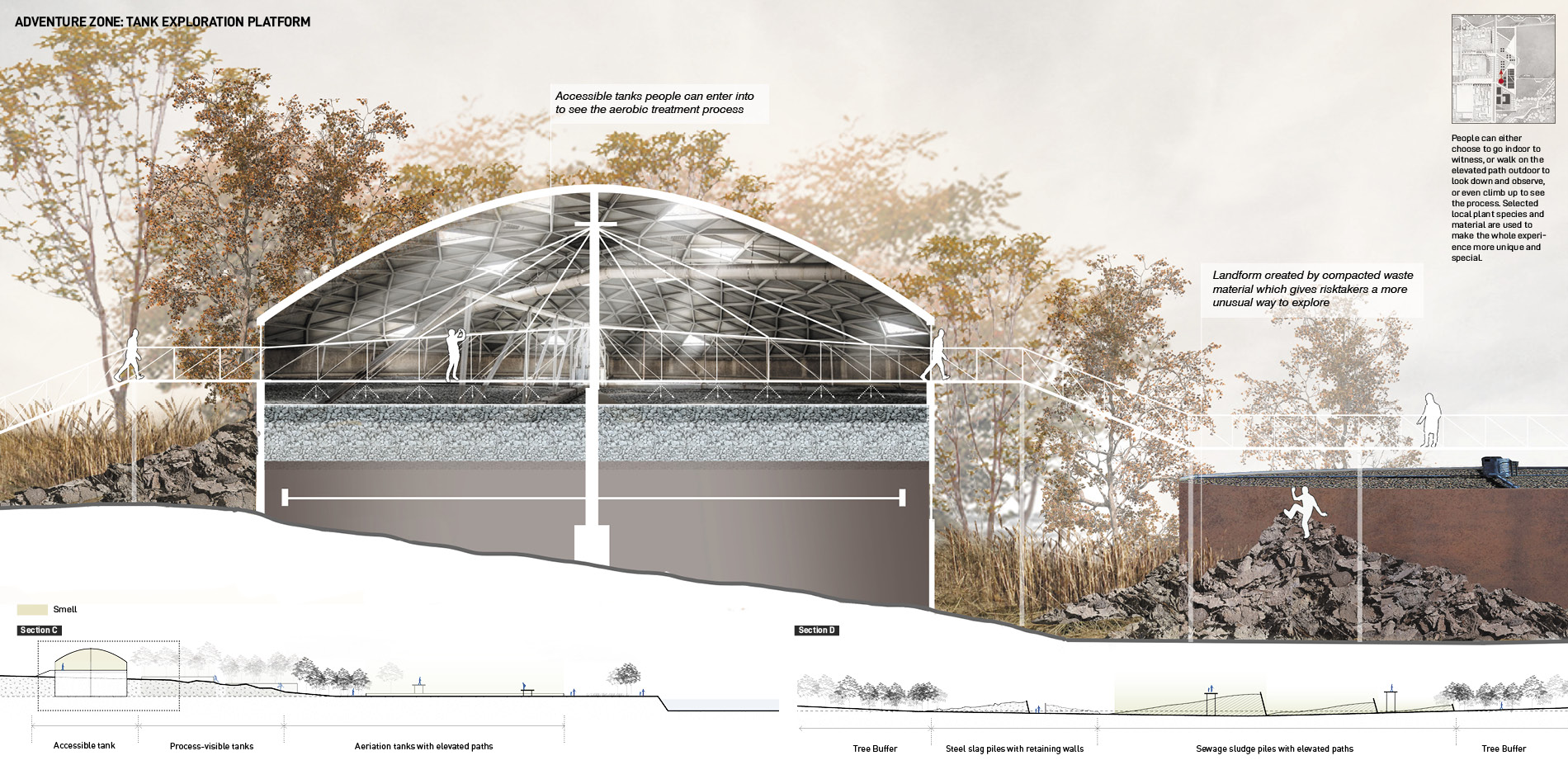

The existing sewage plant is expanded to cater for the increasing demand of greywater treatment from the ongoing urbanization. Waste materials such as steel slag and sludge from steel production and on-site dredging leave large amounts of soil fill as a great opportunity to use landform strategies to present people with various ways to explore and participate in the treatment process. These intimate experiences can ease common feelings of loss and dissociation evoked by giant industrial machines, further bridging the gap between people and place. The recycled waste materials are now turned to public amenities to highlight the unique industrial identity of the site.

From primary to tertiary treatment, as the unpleasant aspects of sewage plants decrease, the water becomes safer for people to interact with. Thus, the space becomes more public. Treatment tanks are arranged along the gradient of accessibility to provide visitors with different modes of exploration, from those that are safer to those that require a more adventurous spirit. Sewage sludge is piled according to different treatment phases releasing different degrees of smell, further diversifying the sensorial experiences of the users.

By transforming invisible to visible, imperceptible to sensible in this proposed water-loop system, a cultural nexus is formed for people to innovatively participate in various treatment processes that help address the local and regional water crisis while also attracting external flows of users and investments to the region.

The steel-making industry acts both as a strong collaborator and a co-beneficiary during this process. It performs as a sustainable counter-act against its own outdating production modes. This proposal thus takes a strong stand as a pioneer project of industry and people co-evolving in lieu of the changing environment.

Plant List:

- Potamogeton pectinatus

- Myriophyllum aquaticum

- Iris wilsonii

- Schoenoplectus

- Iris pseudacorus L.

- Typha orientalis

- Lythrun salicaria L.

- Salix babylonica

- Sophora japonica

- Arundo donax 'Zebrinus'

- Elaeagnus angustifolia

- Achnatherum splenders Nevski

- Weigela florida

- Ziziphus jujuba

- imperata cylindrica 'Rubra'

- Phyllospadix japonica

- Kochia scoparia

- Tamarix chinensis

- Suaeda maritima

- Phragmites communis

- Suaeda salsa